Sorry, the information is not available in english.

You can read it in spanish by clicking here.

SMAC: sublimation of precision

SMAC manufactures electric actuators based on voice coil technology. It was founded in 1990 in Carlsbad (USA), where it is headquartered. It currently has production centers in the USA, Europe and Asia, enabling it to offer a global service.

More than 30% of SMAC’s employees are highly qualified engineers. SMAC prides itself on being a business run by engineers for engineers.

SMAC moving coil actuators are used in many different applications in a wide variety of industries. Their number is growing steadily, while their cost is dropping to the level of pneumatic components, with the advantage of being able to precisely control position, force and speed.

SMAC technology

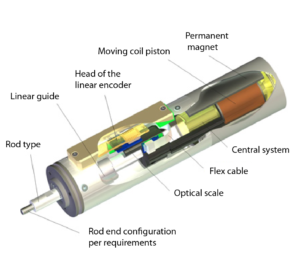

For the production of its actuators, SMAC uses voice coil technology, the working principle of which is the same as that used in loudspeakers. One or more coils are placed in a magnetic field generated by permanent magnets, and by circulating current through the coil, a magnetic field is generated which interacts with the fixed field. The mechanical force produced by this interaction will be directly proportional to the number of turns of the coil and the current flowing through the coil.

In SMAC actuators it is the coil that moves, not the magnets, which allows extreme speeds and accelerations to be achieved due to their low weight.

The actuators are designed to operate at exceptionally high or low speeds with sub-micron accuracy and high repeatability. This makes them ideal for a wide range of positioning, measuring, inspection and pick-and-place applications, especially where 100% verification is required. Specifically, SMAC electric actuators are widely accepted in industries such as automotive, glass processing, electronics, health sciences and packaging, among others.

Soft-Land

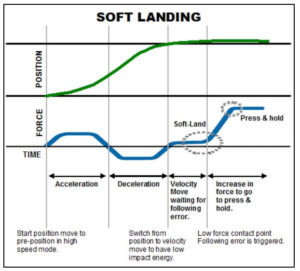

“Soft-Land is a patented SMAC technology consisting of a software routine that gives the actuator stem, or the fingers of a gripper, the ability to stop on the surface of a part with a programmable force as low as necessary. This is particularly useful when handling delicate or expensive components.

The routine achieves a low-force, controlled approach in velocity mode by constantly monitoring the position error. Once contact is made, the position error is accumulated until a pre-defined limit is reached by exerting a programmed force on the workpiece surface.

Advantages of SMAC Electric Actuators

- Full control of force, position, velocity and acceleration

- High accuracy, repeatability and durability

- Integrated measuring system with optical scale down to 0.1 µm (wear-free)

- High mechanical robustness and long service life due to oversized linear guides

- Force measurement via motor power consumption

- Digital and analogue inputs and outputs

- Possibility to switch between force, position or speed modes within the cycle

- Extreme speed and acceleration values due to low inertia (the coil moves, not the magnets)

- Unique “Soft-Land” function

Categories

Contact Larraioz Elektronika to get further information about SMAC product categories: info@larraioz.com

Or if you prefer, you can read it in Spanish by clicking here.