LinMot: Reliability and hight dynamics

The tubular style linear motors and controller from LinMot are built for use in demanding industrial environments. Their exceptional technical properties, low maintenance and high service life place them in a unique position.

Speeds of up to 7.3 m/s and accelerations of over 780 m/s2 allow very short positioning times and high cycle rates.

Within the wide range of solutions, LinMot provides electrical actuators for complex servo applications or simple replacement of pneumatics, extremely high dynamic tubular linear motors, rotary and linear integrated units and magnetic springs. The LinMot technology has proven over the years that it is an ideal solution in many application sectors, such as packaging, food, beverage, textile machinery, medical and pharmaceutical, automotive, labeling, wood, etc.

NTI AG is a global manufacturer of high quality tubular style linear motors and linear motor systems that focuses on the development, production and distribution of linear direct drives to be use in industrial environments. Founded in 1993 as an independent business unit of the Sulzer Group, NTI AG has been in operation since 2000 as an independent company. NTI AG headquarters are located in Spreitenbach, near Zurich in Switzerland and it has three production sites in Switzerland and Slovakia.

The brands LinMot® for industrial linear motors and MagSpring® for magnetic springs, are offered to customers worldwide. NTI AG maintains an experienced customer consultant sales and support network of over 80 locations worldwide. For the realization of linear motion, NTI AG is always a competent and reliable partner.

Mission

LinMot offers its customers a sophisticated and dedicated linear drive system that can be easily integrated into all leading control systems. The high degree of standardization, the capacity to deliver from stock and the worldwide distribution network, ensure an immediate availability and an excellent customer support. The product range is adjusted to provide the customer with all the necessary components for linear drive systems from a single source. Due to continuous product additions, it is the company’s intention to extend the range of linear motors steadily.

Our aim is to boost the linear direct drive technology and turn it into a standard element in the machine design. We offer highly efficient drive solutions that make a major contribution to the overall resource conservation effort.

Linear motors

Whenever translational motions need to be performed dynamically with low friction and high flexibility, users choose linear systems. The core of the LinMot drive system consists of the control electronics, the servo drive, and the linear motors.

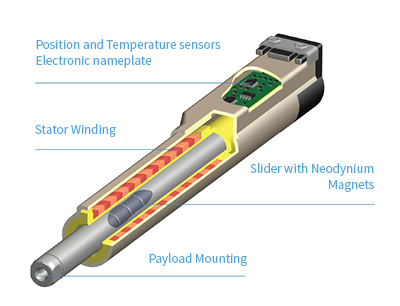

LinMot motors are electromagnetic direct drives in tubular form. The linear motion is produced purely electrically and wear-free, without any intermediate coupling of mechanical gearboxes, spindles, or belts. The linear motor consists of just two parts: the slider and the stator. The slider is made of neodymium magnets that are mounted in a high-precision stainless steel tube. The stator contains the motor winding, bearings for the slider, position capture sensors, and a microprocessor circuit for monitoring the motor.

- can be positioned freely

- extremely dynamic

- long service life

- adjustable speed

- monitored motions

- adjustable acceleration

- gentle motions

- programmable force

- can be synchronized

The internal position sensor measures and monitors the current position of the linear motor not only when it is stopped, but also during the motion. Deviations in position are detected immediately and reported to the upper-level controller. LinMot linear motors can be positioned freely within the entire range of the stroke. In addition, both the travel speed and the acceleration can be controlled precisely. For more complex motions, arbitrary travel profiles can be saved as curves in the servo drive and executed by the motor at the desired speed.

Speeds of up to 7.3 m/s and accelerations of over 780 m/s2 allow very short positioning times and high-frequency cycles.

The design of the linear motors makes them the standard elements in the field of machine design, where are commonly used for replacing pneumatic drives and mechanical cam discs. With LinMot linear motors and simple guides, the engineer has all the needed components to design complete linear drive systems.

|

LinMot training |

|---|

Tubular style linear motors, for extremely high dynamic applications, speeds up to 7.3m/s, acceleration up to 780m/s2, short positioning time and high frequency operations

Developed fully in stainless steel, provide hygiene at the highest level. Optimum solution for processing food products or pharmaceuticals

Linear and rotary movements on a single component. High dynamic lineal and rotary sequences, synchronous or completely independent of each other

Compact position controllers for LinMot servo motors. A wide range of fieldbus interfaces for a simple integration in any control concept.

Compact guide units for LinMot linear motors. Load guiding at same time that support external forces and bending moments